ASHCROM -G70

Product Details:

- Form Liquid Coating

- Color DARK BROWN

- Click to View more

ASHCROM -G70 Price And Quantity

- 5 Kilograms

- 200.00 - 250.00 INR/Kilograms

- 200 INR/Kilograms

ASHCROM -G70 Product Specifications

- Liquid Coating

- DARK BROWN

ASHCROM -G70 Trade Information

- HDFE CAN

- All India

- ISO CERTIFIED

Product Description

ASHCROM G-70

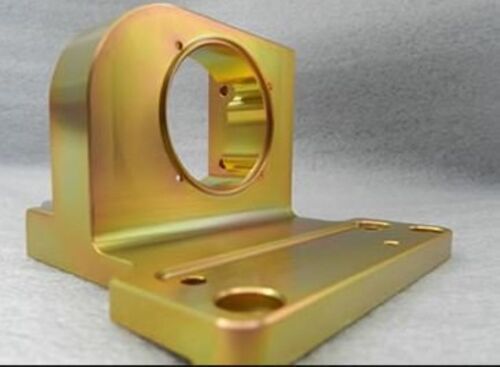

(YellowChromate Conversion coating for aluminium & its alloys)

Ourabove product is in highly concentrated liquid form and with small quantity inwater, it produces yellow conversion coating on aluminium which has bettercorrosion resistance and paint bonding.It is used as a low cost substitute for anodizing and with additionaldesirable properties. The process isvery simple and easy to operate. Yellowcoating is produced in the ASHCROM bathby short time immersion at room temperature or by spraying or brushing.

Thefilm thickness and colour can be varied by changing the bath concentration andtreatment time. The thinnest films areclear. As the thickness increases,colour develops as a light yellow and finally medium brown. The corrosion resistance and colour ofchromated aluminium varies with alloy composition. It depends further on film thickness. High silicon alloys have much less corrosionresistance whereas copper alloys have better corrosion resistance.Common practice is to use chromate treatment plus a primer and a topcoat to obtain a finish of maximumprotective value and durability.

Lowelectrical resistance makes chromate films highly suitable for many electronicapplication. Ground connections can bemade to treated aluminium chasis without removing the protective film. Other parts such as booster nozzles, waveguides, connectors & aluminium cabinets, missile and other aircraft andmilitary components can be chromated with this ASHCROM treatment. Thischromate coating is conductive in nature.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+